BILSTEIN

SHOCK ABSORBERS & SUSPENSION – A WORLD ICON in

the industry!

Proven design

technology, a superior manufacturing process and

a commitment to quality control characterise the

Bilstein shock absorber production process. At

Bilstein over 40% of the production personnel

are involved with quality control to maintain

their industry-leading level of shock absorber

efficiency and long life performance. In this

pursuit of excellence, Bilstein has received

worldwide acclaim for quality shock absorbers

that have set new industry standards. Setting

high standards has always been a top priority

with Bilstein and a consistent set of parameters

and performance guidelines go into the

development of each Bilstein shock application.

Bilstein engineers meld proven methods with the

most advanced technologies for products that

pass the test of time.

They perfected the mono-tube gas pressure shock

absorber, a new design which revolutionised the

shock absorber industry in Germany and the

world. August Bilstein established 16 worldwide

patents on the development of their mono-tube

gas pressure shock absorber design. They worked

closely with Daimler-Benz and in 1958 Bilstein

became standard equipment on all Mercedes-Benz

models, beginning an association that continues

today. To further strengthen their position with

automotive manufacturers worldwide, Bilstein

outfitted factory race cars with their shock

absorbers to demonstrate their superior

performance. This started an unparalleled record

of motor sports success at racing venues the

world over.

BILSTEIN

TECHNOLOGY - Control Stability

BILSTEIN

TECHNOLOGY - Control Stability

Driving a vehicle equipped with Bilstein Gas

Pressure Shock Absorbers is an exhilarating

experience.

There is, quite literally, nothing like it.

Unbelievable control and stability.

Precise handling.

Ultimate performance and comfort.

Fully Rebuildable and Revalvable

Bilstein has been a unique and driving force in

the automotive suspension industry. Bilstein was

first to apply the patented gas pressure

principle to controlling ride characteristics on

automobiles and introduced the world's first

mono-tube gas pressure shock absorber. Today,

Bilstein continues to be the leader in mono-tube

gas pressure shock absorber technology. No other

shock manufacturer has been able to equal the

performance and enhanced ride characteristics of

the Bilstein shock.

From racing and testing in Formula 1, NASCAR,

Rallying and Off Road to original equipment on

BMW, Ferrari, Jaguar, Mercedes Benz, Porsche,

Subaru, Toyota, TRD, GM, Ford, and Chrysler

vehicles, Bilstein Gas Pressure Shock Absorbers

have proven to be the best.

Ride, handling and control are what a shock

absorber provides. Bilstein's patented design

reduces the need for compromise.

The rising rate valving of the Bilstein shock

absorber provides the necessary damping to react

quicker to road conditions without sacrificing

ride comfort. This combination of valving and

high pressure nitrogen gas @ around 25

atmospheres of pressure keeps the tires in

constant contact with the road helping to ensure

safety through enhanced control.

ADVANCED TECHNOLOGY » BETTER BY DESIGN

Heat is one of the major detriments to the

performance and longevity of any shock absorber.

Conventional designed shocks trap the heat

within the shock body and preventing adequate

dissipation, making them prone to heat build up,

fade and eventual failure.

Bilstein's technically superior, patented

mono-tube Hi-Pressure gas charged design allows

the excessive heat from the oil to transfer to

the outer surface of the shock body and

dissipate more efficiently. The dividing piston

also permits the oil to expand as heat builds,

preventing aeration (foaming) and viscosity loss

and increasing the pressure of the gas on the

oil coulumn. This allows the shock to maintain

full damping characteristics as temperatures

rise.

|

Superior Mono-tube Design & Fabrication

The tube of a Bilstein Gas Pressure

Shock Absorber is fabricated using a

special extrusion method. This process

achieves an extremely tight

peak-to-valley tolerance and maintains

consistent wall thickness. Bilstein's

seamless mono-tube design provides

superior tube strength while maximizing

heat dissipation and shock absorber

life.

|

ADVANCED

TECHNOLOGY » BETTER BUILT

Most conventional shocks are made with shock

bodies cut from a piece of steel tubing, stamped

internal parts and compromised tolerances.

In contrast, Bilstein's shock bodies are

precision formed through a unique seamless

extrusion process. This provides superior

strength along with high finish tolerances that

are usually associated with surgical

instruments. The shock body is then treated with

a special paint finish durable enough to

withstand gruelling 240-hour salt spray tests.

The finished body is mated with a solid,

induction hardened steel chrome plated and

polished shaft, machined valving components and

highest quality seals. Combined with extreme

attention to detail, Bilstein manufactures the

closest thing to a hand built shock available

today.

Digressive Working Piston Assembly

The piston head design allows independent tuning

of the compression and rebound damping forces to

provide optimum ride comfort and performance

without compromise. It features fewer parts than

most conventional twin tube and so called "road

sensing" shock designs. This simple, yet

exceptionally functional digressive design

contributes to the extreme durability and long

life of Bilstein Shock Absorbers.

PATENTED PERFORMANCE » SAFER DRIVING THROUGH

SUPERIOR CONTROL...

Ride, handling and control are what a shock

absorber provides. Compromise in one area may

create a problem in another. Bilstein's patented

design reduces the need for compromise. The

rising rate valving of the Bilstein shock

absorber provides the necessary damping to react

quicker to road conditions without sacrificing

ride comfort. This combination of valving and

high pressure nitrogen gas keeps the tires in

constant contact with the road helping to ensure

safety through enhanced control.

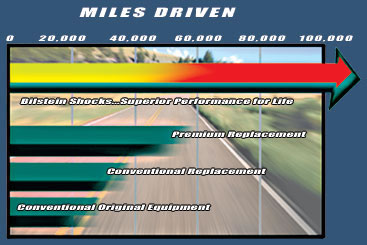

KILOMETRES 0k

30,000k 65,000k

95,000k 125,000k

160,000k DRIVEN

Conventional shocks slowly lose efficiency

and eventually fail over a period of time,

causing excessive tire and suspension

component wear, a loss of control of the

vehicle and longer braking distances.

Bilstein shocks continue to deliver

optimum performance for a much longer

life.

Of

all a vehicle's suspension components, nothing

works harder than the shock absorbers, making it

critical to pick the correct ones. Bilstein Gas

Pressurised Shock Absorbers are the best way, to

dramatically improve the ride, handling and

control of your 4WD recreational vehicle that

spends 80-90% of it’s life in the urban jungle

and along our freeway and poor highway and

secondary bitumen and dirt roads roads. These

are the driving conditions that benefit most

from the Bilstein ‘Rising Rate’ Mono-Tube Gas

experience.

Please use the "Shop By

Vehicle" list in the LHS column of our Home Page

for your application

If you don’t find them listed for your

vehicle as yet, give us a call or email us!